Aluminum Mig Welding Settings Chart

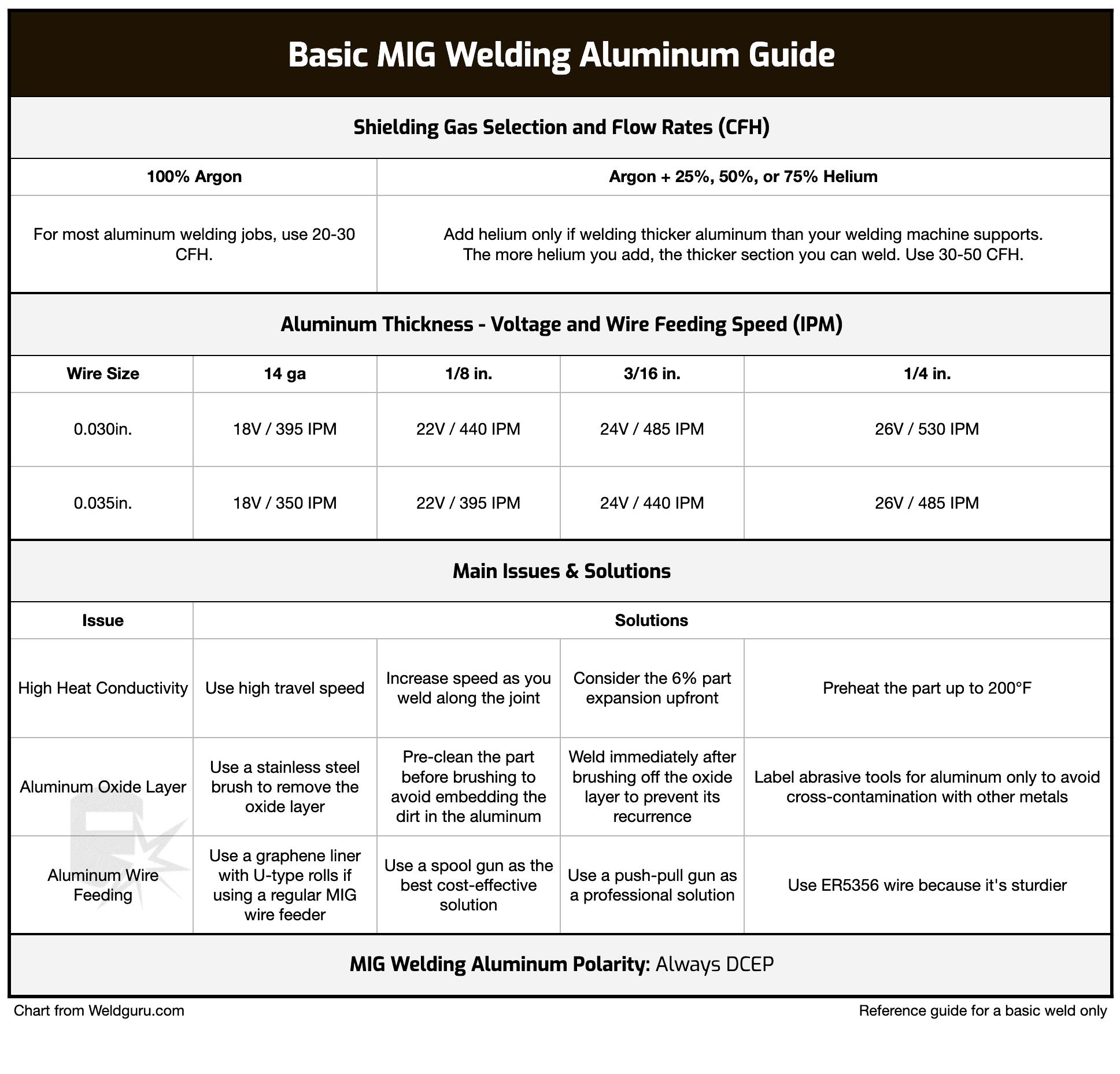

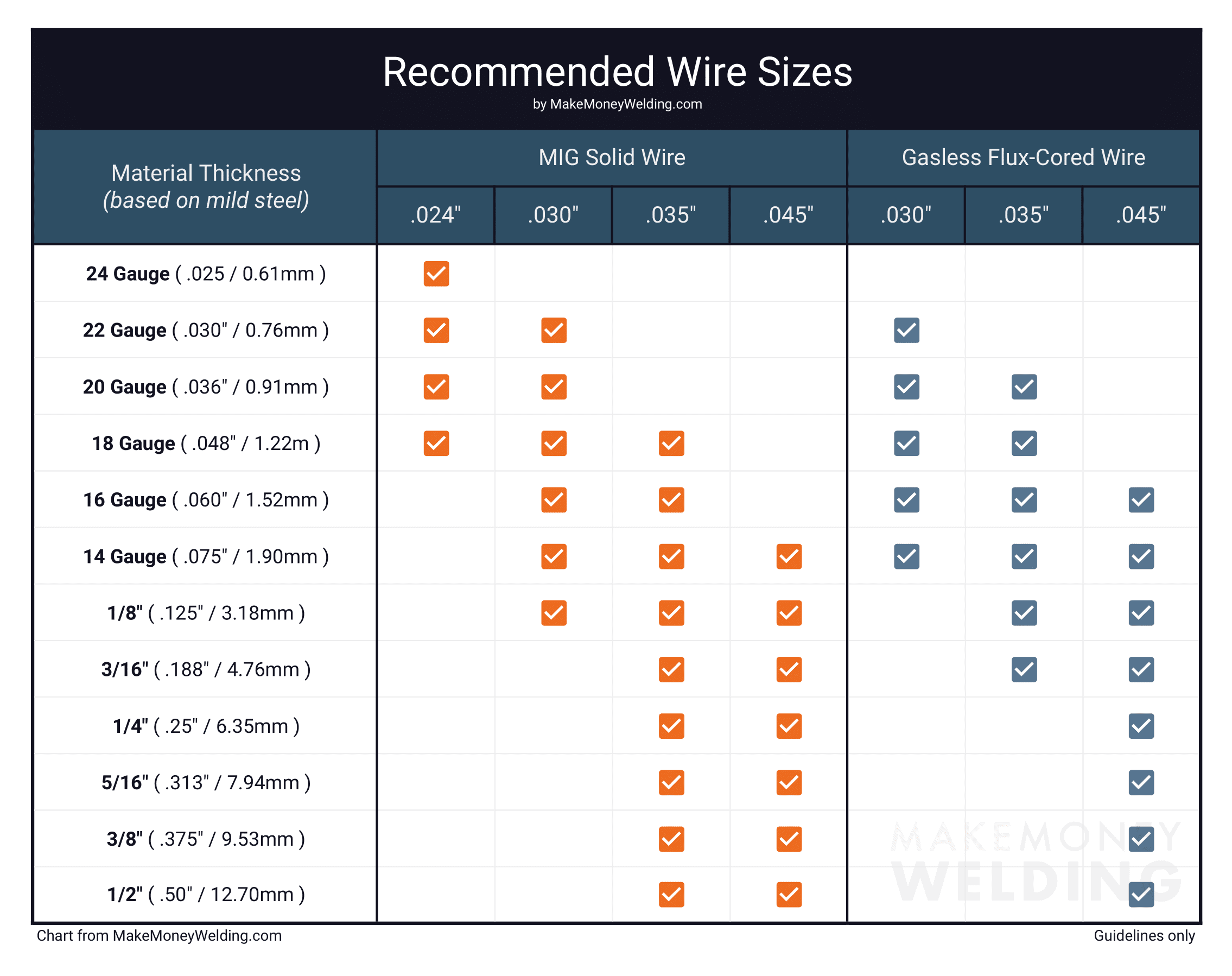

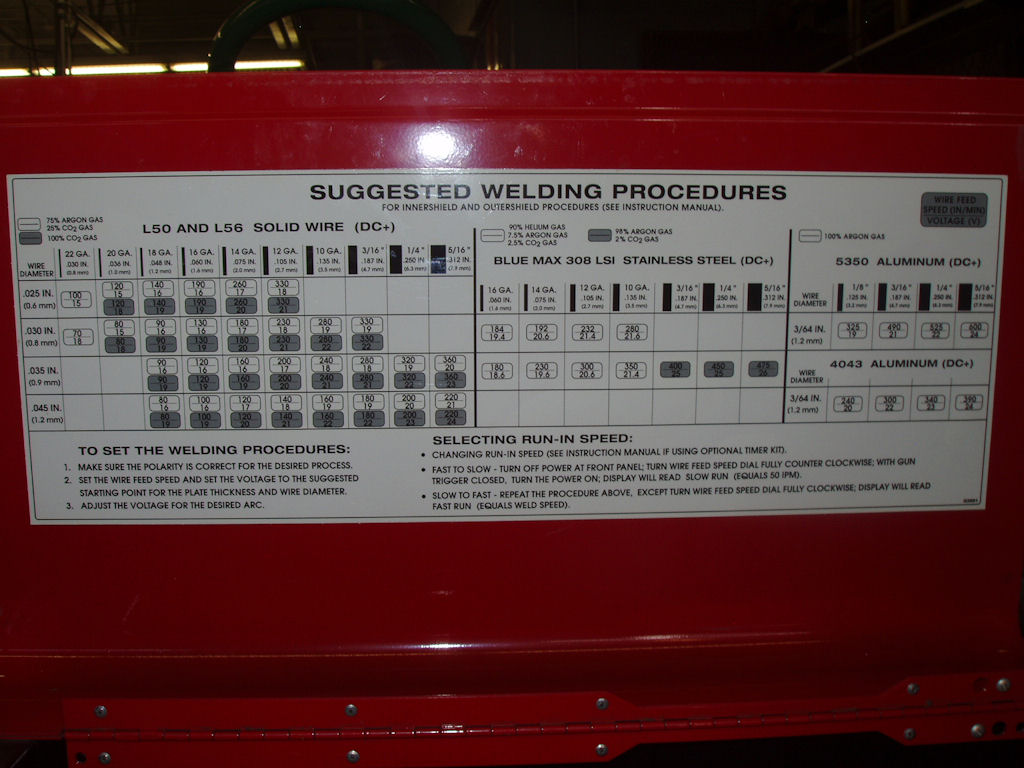

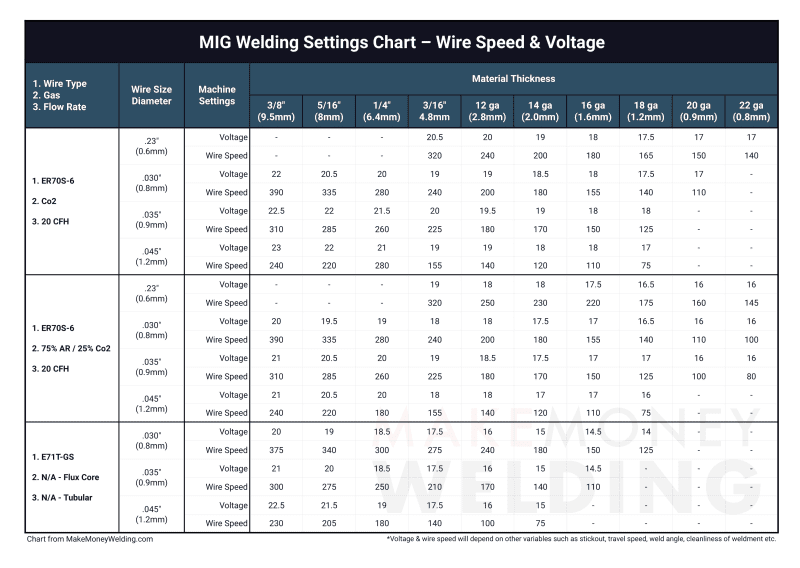

Aluminum Mig Welding Settings Chart - Web here are charts showing the wire speed and voltage speed settings required for mig aluminum welding. But before using these values, we suggest that you have a decent understanding of your preferred metal. However, you will need special wire if you plan to weld other metals, such as aluminum. Web the chart below shows minimum and maximum gas flow rates for standard mig nozzle diameters for argon mixtures and co 2. Web as a guideline, each.001 inch of material thickness requires 1 amp of output: Web gas metal arc welding (gmaw), also known as mig welding, can be used very effectively on aluminum with good practice. You will also learn how to adjust essential variables, such as voltage and wire feed speed. You choose your wire size by the amperage setting, which in turn depends on material thickness. Web removing the oxide. Web below is the mig welding aluminum sheet metal settings chart which displays the recommended settings for welding aluminum sheet metal. Web mig welding is also called as gas metal arc welding (gmaw) is a type of welding that is done using a continuously fed mig wire electrode and a shielding gas that melts and deposits the workpiece metal in the weld joint. Web below is the mig welding aluminum sheet metal settings chart which displays the recommended settings for welding aluminum sheet metal. What’s the right technique for mig welding aluminum? Pulling or using a drag angle will produce porous, dirty welds because of lack of gas coverage. The best filler materials for mig welding aluminum include brass shim stock, bronze wire, nickel silver sheets, and copper brazing. What settings are best for mig welding aluminum? Web in mig welding, you will be mostly using argon, helium, co2, or a touch of oxygen. Can you mig weld aluminum? Share this | print this. But before using these values, we suggest that you have a decent understanding of your preferred metal. Share this | print this. Download the app version of the weld setting calculator for easy reference! The most common metals welded with the mig process include mild steel, stainless steel, and aluminum. The best filler materials for mig welding aluminum include brass shim stock, bronze wire, nickel silver sheets, and copper brazing. As part of the process, you will. .125 inch = 125 amps. What equipment is necessary to mig weld aluminum? However, you will need special wire if you plan to weld other metals, such as aluminum. Web from detailed settings charts that guide you through the intricate world of voltage, amperage, and wire feed speed, to a breakdown of the best aluminum mig wire for various applications,. Web removing the oxide. Web the chart below shows minimum and maximum gas flow rates for standard mig nozzle diameters for argon mixtures and co 2. Web as a guideline, each.001 inch of material thickness requires 1 amp of output: Web consider these welding techniques to help enhance your skills. In addition, the wire types (filler material) should suit the. Web mig welding is also called as gas metal arc welding (gmaw) is a type of welding that is done using a continuously fed mig wire electrode and a shielding gas that melts and deposits the workpiece metal in the weld joint. Web recommended mig aluminum welding setting for wire diameters, wfs, amperage, welding voltage and gas flow rate are. I say do it with a hand wire brush or a cup wire brush. What equipment is necessary to mig weld aluminum? Web consider these welding techniques to help enhance your skills. Web the chart below shows minimum and maximum gas flow rates for standard mig nozzle diameters for argon mixtures and co 2. Web our 15 tips and tricks. Web from detailed settings charts that guide you through the intricate world of voltage, amperage, and wire feed speed, to a breakdown of the best aluminum mig wire for various applications, i’ve got you covered. Web gas metal arc welding (gmaw), also known as mig welding, can be used very effectively on aluminum with good practice. You choose your wire. You choose your wire size by the amperage setting, which in turn depends on material thickness. Filler rods of the proper alloy. As part of the process, you will learn how to select the correct filler metal for the specific type of aluminum that you plan on welding. Share this | print this. A power wire brush can be used,. If you are welding mild steel (carbon steel), the best choices are c25 gas type (75% argon and 25% carbon dioxide) and er70s electrode. Aluminum is a unique material to weld and requires special settings compared to other metals. Web the chart below shows minimum and maximum gas flow rates for standard mig nozzle diameters for argon mixtures and co. Since you don't want to change wire, select one for your most commonly used thicknesses. .125 inch = 125 amps. What material are you welding? You choose your wire size by the amperage setting, which in turn depends on material thickness. Web mig welding is also called as gas metal arc welding (gmaw) is a type of welding that is. Aluminum is a unique material to weld and requires special settings compared to other metals. Web watch as alvin kirksey, hobart welding engineer, explains how to set up the miller® alumafeed® synergic mig aluminum welding system paired with hobart® maxalmig® 4943 aluminum welding. Web from detailed settings charts that guide you through the intricate world of voltage, amperage, and wire. Download the app version of the weld setting calculator for easy reference! I say do it with a hand wire brush or a cup wire brush. Web in mig welding, you will be mostly using argon, helium, co2, or a touch of oxygen. Select proper wire size according to amperage. Web as a guideline, each.001 inch of material thickness requires 1 amp of output: In this video, we complete welds both with and without a spool gun. But before using these values, we suggest that you have a decent understanding of your preferred metal. This will be good for most jobs up to about ½”. Web gas metal arc welding (gmaw), also known as mig welding, can be used very effectively on aluminum with good practice. However, you will need special wire if you plan to weld other metals, such as aluminum. But before using these values, we suggest that you have a decent understanding of your preferred metal. Share this | print this. Can you mig weld aluminum? Pulling or using a drag angle will produce porous, dirty welds because of lack of gas coverage. What’s the right technique for mig welding aluminum? In addition, the wire types (filler material) should suit the base metal, and here are some recommendations.Mig Welding Settings Chart

How To MIG Weld Aluminum Beginners Guide (with Chart)

How To MIG Weld Aluminum Beginners Guide (with Chart)

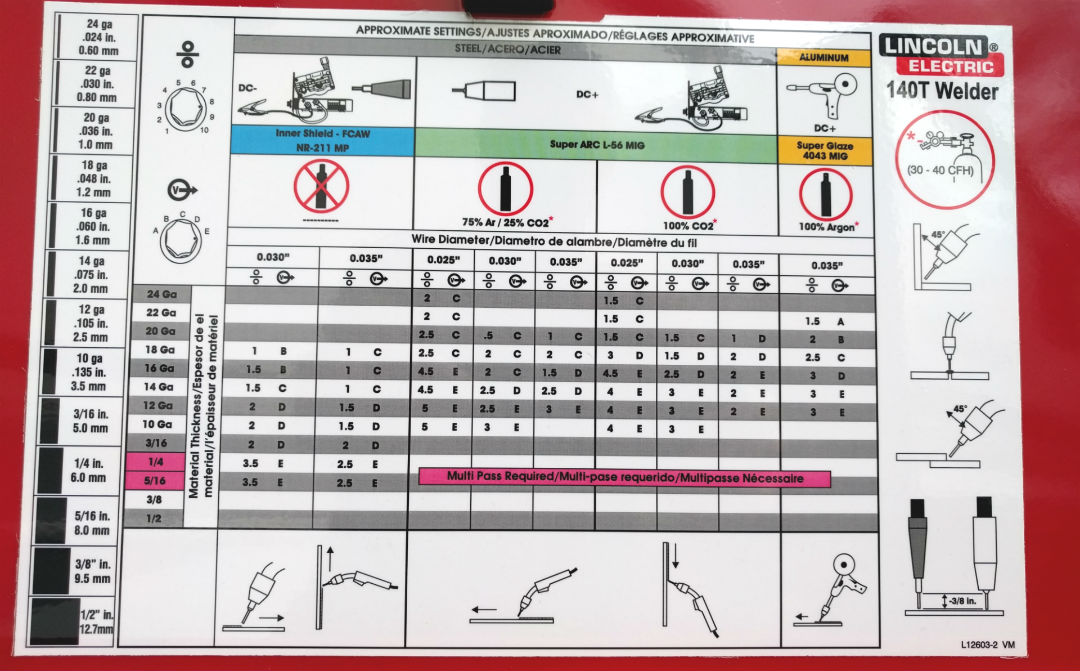

MIG Welder Settings Explained (with Chart) Weld Guru, 49 OFF

MIG Welder Settings Explained (with Chart) Weld Guru

MIG Welding Aluminum Electrodes, Gasses, Welder Setting & Equipment

Aluminum Mig Welding Parameters

Important MIG Welder Settings You Need to Know (with Chart)

MIG Welder Settings Explained (with Chart) Weld Guru, 49 OFF

Mig Welding Chart Settings And Guides

What Equipment Is Necessary To Mig Weld Aluminum?

Web Removing The Oxide.

Web Watch As Alvin Kirksey, Hobart Welding Engineer, Explains How To Set Up The Miller® Alumafeed® Synergic Mig Aluminum Welding System Paired With Hobart® Maxalmig® 4943 Aluminum Welding.

If You Are Welding Mild Steel (Carbon Steel), The Best Choices Are C25 Gas Type (75% Argon And 25% Carbon Dioxide) And Er70S Electrode.

Related Post: